- Detail

- Parameters

- Review

NITRIDING SCREW/TUBE

Using high-quality nitriding steel SACM645 or SKD61 after quenching, the surface is vacuum nitrided. The nitriding furnaceis developed and improved to evenly distribute the gas in thefurnace by means of blade fan stirring, so that the surfacenitriding treatment of the product is more stable and uniform.Provide customers with more perfect quality.

Corresponding plastic raw materials

ABS, PP, PS, PE, TPU, TPE and other common plastics.

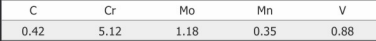

Nitriding screw/barrel chemical composition

Chemical composition(%):

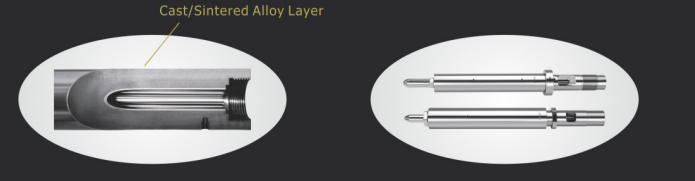

ALLOY TUBE

The double-alloy material tube is a layer of 2~3mm alloy powderthat is centrifugally cast in the inner hole of the material pipe athigh temperature to enhance the wear resistance, corrosion resistance and high temperature resistance of the inner hole.Sintered double-alloy material tube with high density and thickness of 0.8~1.2mm,which further prolongs the service life. Different alloy formulations can be selected according to product requirements.

Halogen-free sintered tube (corresponding to halogen-free special screw)

Features: Super corrosion resistance, wear resistance, hardness HRC58~62°;

A-grade Ni+WC alloy tube (corresponding to powder stainless steel A-grade screw)

Features: High corrosion resistance, wear resistance, hardness HRC60~64°;

B-grade Fe+Ni alloy tube (corresponding to fully hardened B-grade screw)

Features: High wear resistance, moderate corrosion resistance, hardness HRC56~60°;

Application industry

Toys,general shells, household appliances, soft rubber,extrusion industry.